Last month, we talked about lithography printing, how it works, what it makes, and how it can be applied in the modern world of printing and publication. Moving forward, we want to expand on a topic that has more modern origins.

For this month’s segment, let’s talk all about digital printing!

The history of digital printing

The origins of digital printing can be traced back to the invention of electrophotography by Chester Carlson in 1938, which used a beam of directed ions to create an electrostatic charge on a rotating drum. A fine powder could then be dusted upon the drum; the powder would stick to the parts of the drum that had been exposed to light, forming an image. This was the basis of the first photocopiers and laser printers (Dillon, 2023).

In 1977, the fastest photocopier was invented, to successfully print text or graphics, the method used suspended particles in imaging oil, forming a thin plastic layer on the surface of a paper. This was called Indigo Printing, named after the company that developed it.

In 1985, office laser printers grew in popularity as they provided higher-quality prints without an overly complicated process (Dillon, 2023). They used toner cartridges containing dry powder ink which was transferred to paper by heat and pressure. Laser printers at this point in time produce sharp and accurate images with high resolution and speed.

In 1993, the first digital color printer was introduced by Xerox, which used solid ink technology. Solid ink printers used blocks of wax-like ink that were melted and sprayed onto paper through tiny nozzles. The ink dried quickly and created vibrant and glossy prints with low environmental impact.

Since then, digital printing has continued to improve and diversify, incorporating technologies such as inkjet, thermal, dye-sublimation, and UV-curable printing. Digital printing can now produce high-quality prints on various substrates such as paper, plastic, metal, fabric, wood, glass, and more.

The pros and cons of digital printing

Digital printing offers many benefits over traditional printing methods, such as:

- Cost-effectiveness: Digital printing does not require any setup costs such as plates, dies, or paper rolls. It also reduces waste and inventory costs by allowing for short runs and on-demand printing (Patterson, 2023).

- Speed: Digital printing can produce prints faster than traditional methods, as it does not require any drying time or manual labor. It can also handle complex and variable data with ease.

- Flexibility: Digital printing can print on a wide range of substrates and sizes, as well as create customized and personalized prints with different designs, colors, texts, images, barcodes, QR codes, etc.

- Quality: Digital printing can produce high-resolution prints with accurate colors and sharp details. It can also print gradients, shades, and effects that are difficult to achieve with traditional methods.

However, digital printing also has some drawbacks, such as:

- Cost: Digital printing may be more expensive than traditional methods for large print runs or certain materials or printing techniques. The cost per unit may not decrease as much as with traditional methods due to the fixed cost of ink and maintenance. (Prints.org, 2023)

- Limitations: Digital printing may not be suitable for certain substrates or printing techniques that require special treatments or coatings. For example, digital printing may not work well on corrugated cardboard or metallic foil. It may also have issues with durability or resistance to water, heat, UV rays, or chemicals (Iverson, 2023).

- Color: Digital printing may not be able to match the color accuracy or consistency of traditional methods that use the PMS color system. It may also have difficulties with reproducing certain colors such as metallics or fluorescents.

What kind of custom packaging works best for digital printing?

Digital printing is ideal for product packaging that usually requires the following characteristics to fully optimize your production line:

- Short runs: Digital printing is perfect for small batches of product packaging that need to be produced quickly and affordably. This is especially useful for seasonal products, limited editions, test markets, or prototypes.

- Customization: Digital printing can create unique and personalized product packaging that can enhance customer engagement and loyalty. This is especially useful for e-commerce products, subscription boxes, gift boxes, or promotional items.

- Innovation: Digital printing can create eye-catching and interactive product packaging that can stand out from the competition. This is especially useful for new products, niche markets, or premium brands.

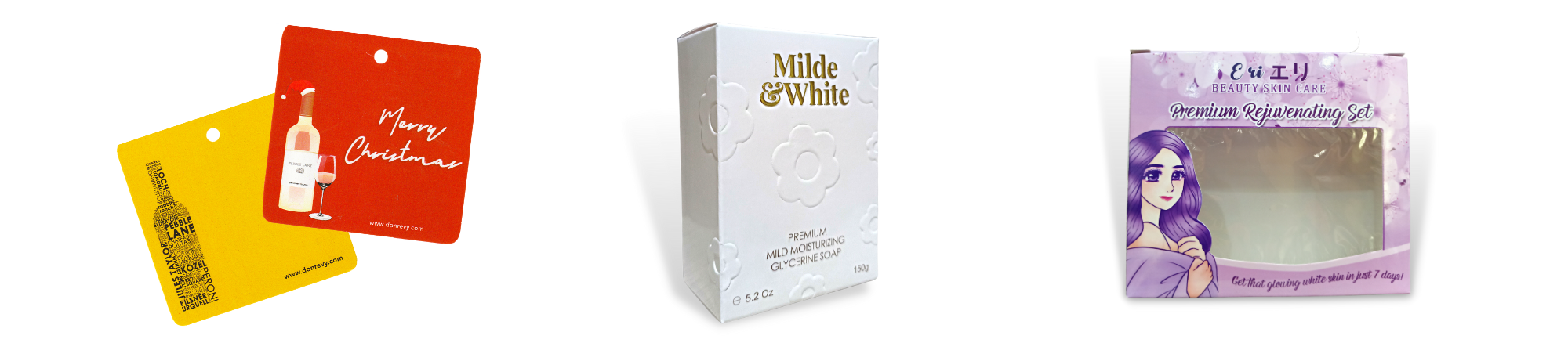

Some practical examples of product packaging that use digital printing are:

- Wine labels: Digital printing can create stunning wine labels that can showcase the brand identity and story of each bottle. It can also print variable data such as vintage year, batch number, or QR code that can link to more information or content online.

- Cosmetic boxes: Digital printing can create elegant and sophisticated cosmetic boxes that can reflect the quality and personality of each product. It can also print different designs, colors, or texts for each product variant or customer preference.

- Food pouches: Digital printing can create flexible and functional food pouches that can preserve the freshness and flavor of each product. It can also print nutritional information, ingredients, or expiration dates that can vary for each product or batch.

Some of the packaging we made for our clients!

That’s about it for digital printing! We hope that this has been another learning experience for you. Tune in next time as we explore more printing methods with this series!

References

Dillon, M. (2023, May 22). The history of Digital Printing: A comprehensive timeline. Meyers. https://meyers.com/meyers-blog/the-history-of-digital-printing-a-comprehensive-timeline/

Patterson, L. (2023, February 23). Digital printing for packaging: An introductory guide. Sttark. https://www.sttark.com/blog/digital-printing-for-packaging-an-introductory-guide

Iverson, J. (2023, July 5). What you need to know about digital printing in packaging – pakfactory blog. PakFactory Blog – The go-to academic resource for packaging. https://pakfactory.com/blog/what-is-digital-printing-packaging/

Digital vs. Traditional Printing: Pros and Cons. Prints.Org. (2023, February 26). https://prints.org/digital-vs-traditional-printing-pros-and-cons/