Late last year, we started talking about some of the printing methods and we began the segment with lithography. Originally, we were planning to discuss just two of the more common methods.

We kind of got into it and before we knew it, we’re now back with our 4th and last “What’s in a Print” segment!

For this month, we want to discuss another tried and tested method. Originally developed between the late 19th and early 20th centuries and originally a staple of newspaper photo features, this printing method is still employed for the commercial printing of publications and postcards among other things (Wikimedia Foundation, 2023).

Without further ado, this month’s discussion is all about Rotogravure Printing!

What is gravure printing?

Rotogravure printing, often simply referred to as gravure, is a high-fidelity printing technique that has been a cornerstone in the world of high-volume production for decades. This method is particularly renowned for its ability to produce crisp, vibrant, and consistent prints, making it a preferred choice for packaging materials and high-quality publications.

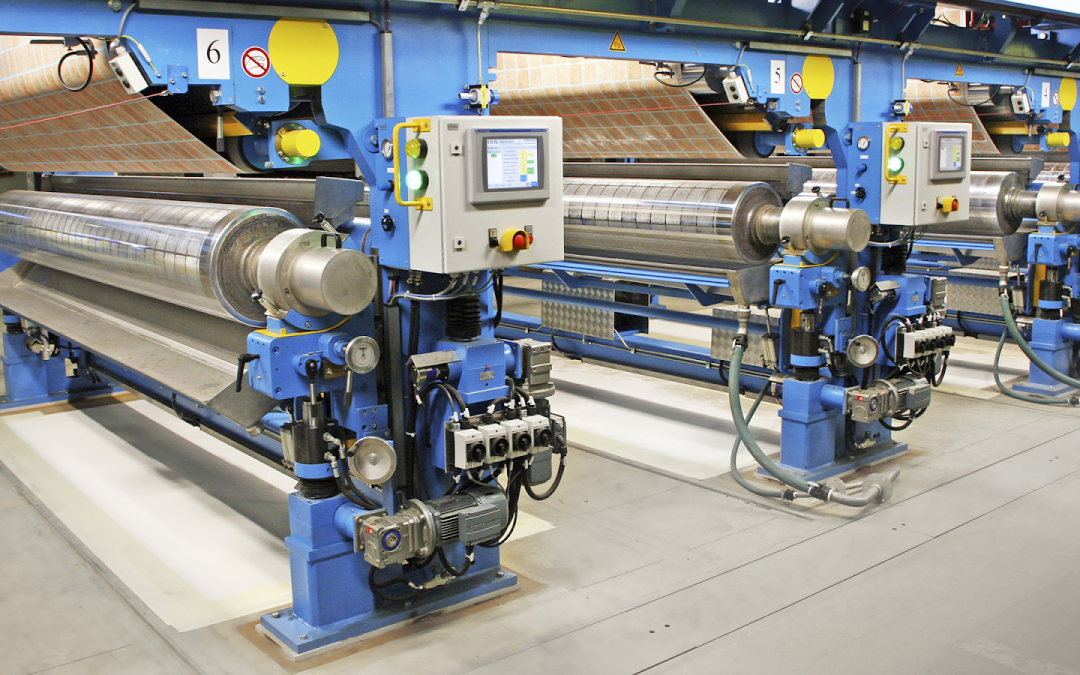

At its core, rotogravure printing is an intaglio printing process, which means it involves transferring ink from engraved grooves or cells onto the substrate. Unlike other printing methods where the image is raised or applied at the surface level, gravure printing requires the image to be etched into the surface of a printing cylinder. This cylinder is then coated with ink, and a doctor blade removes the excess, leaving ink only in the recessed cells. The substrate is pressed against the cylinder, and the ink is transferred from the cells to the paper, film, or another material (Affstuff, 2023).

How does gravure printing work?

The process begins with the creation of the cylinder, which is carefully engraved with the desired image. Modern techniques use laser engraving for precision, ensuring that each cell can hold the exact amount of ink required for the print. The cylinder rotates through an ink fountain, filling the cells (Bear, 2020). A doctor blade then scrapes the cylinder’s surface, leaving ink only in the recesses. The substrate passes between the cylinder and an impression roller, transferring the ink onto the material. The substrate then goes through a dryer before it is rolled up or cut to size (Encyclopædia Britannica, n.d.).

Pros and cons of gravure printing

Advantages:

- High-Quality Prints: Gravure printing is unmatched in quality, capable of producing sharp images and deep, rich colors.

- Consistency: The nature of the printing process ensures uniformity across large runs, which is essential for brand consistency.

- Speed: It is a fast process, suitable for long runs and high-speed production requirements.

- Versatility: This method can print on a wide array of substrates, including paper, foil, and plastic films (PrimetechGravures, 2023).

- Durability: Prints are long-lasting and resistant to wear and fading, ideal for packaging needs (Affstuff, 2023).

Disadvantages:

- High Initial Costs: The cost of engraving cylinders and setting up the press is significant, making it less economical for short runs.

- Long Setup Time: Preparing the cylinders and press can be time-consuming.

- Inflexibility: Once a cylinder is engraved, it cannot be easily altered for new designs.

- Waste: The process can generate higher levels of waste material, particularly during setup (AspiringYouths, n.d.).

When is it ideal to use gravure printing for your packaging?

Rotogravure printing is particularly advantageous for packaging due to its high-quality output and efficiency in long runs (Affstuff, 2023). It’s commonly used for food packaging, where the detail and color fidelity can make products stand out on the shelf. The durability of gravure prints also means that the packaging will withstand handling and shipping without losing its visual appeal.

The process is also well-suited for flexible packaging (Bear, 2020), which requires the print to bend and stretch without cracking or distorting the image. With the ability to print on thin films and foils, rotogravure is ideal for snack bags, wrappers, and other types of flexible containers.

Conclusion

Rotogravure printing stands as a testament to the enduring power of traditional printing methods in an increasingly digital world. Its ability to produce high-quality, consistent, and durable prints ensures its continued relevance in the packaging industry and beyond. While it may not be the most cost-effective option for small runs, its advantages make it an unbeatable choice for large-scale production needs.

That’s about it for our “What’s in a Print” series! We hope you learned as much as we did on this segment. Once again, stay Cr8tive, and see you next time!

References

Wikimedia Foundation. (2023, October 19). Rotogravure. Wikipedia. https://en.wikipedia.org/wiki/Rotogravure

Encyclopædia Britannica, inc. (n.d.). Gravure printing. Encyclopædia Britannica. https://www.britannica.com/technology/gravure-printing

Bear, J. H. (2020, February 14). What is gravure printing and how does it work?. Lifewire. https://www.lifewire.com/what-is-gravure-printing-1074611

PrimetechGravures. (2023, July 18). A short overview on pros and cons of gravure printing. Medium. https://medium.com/@primetechgravures/a-short-overview-on-pros-and-cons-of-gravure-printing-4d4d42dec707

Advantages and disadvantages of gravure printing. AspiringYouths. (n.d.). https://aspiringyouths.com/advantages-disadvantages/gravure-printing/

What is rotogravure? A beginner’s guide. Affstuff. (2023, October 17). https://affstuff.com/glossary/rotogravure/